The golf apparel industry is experiencing a revolutionary transformation as manufacturers embrace sustainable practices without compromising on quality, performance, or efficiency. Today's golf fashion emphasizes sustainability, versatility, and comfort, with eco-friendly materials and modern designs reflecting the evolving preferences of contemporary golfers. For golf apparel startups, procurement managers, and fashion buyers, understanding these sustainable manufacturing practices is crucial for building successful, environmentally conscious brands.

The Evolution of Sustainable Golf Apparel Manufacturing

Between 2025 and 2035, the golf apparel industry will be more devoted to sustainable innovation, intelligent textile technology, and inclusive design. This shift represents more than just a trend—it's a fundamental reimagining of how golf clothing is produced, distributed, and consumed.

Modern golf clothing solutions now prioritize recycled materials, efficient manufacturing processes, and innovative technologies that reduce environmental impact while enhancing performance. As a leading golf clothing manufacturer, Leto Golf understands that today's brands—whether they're golf apparel startups or established companies—demand suppliers who can deliver both sustainability and excellence.

Understanding the Market Demand

The demand for eco-friendly golf apparel for environmentally conscious brands has surged dramatically. Golf enthusiasts, particularly younger players, increasingly seek clothing that aligns with their environmental values without sacrificing the technical performance required on the course. This creates unique opportunities for golf shirt suppliers who can meet these dual demands.

Sustainable Materials: The Foundation of Green Golf Apparel

Recycled Golf Apparel: Leading the Charge

Recycled golf apparel suppliers are at the forefront of this sustainable revolution. Major brands are now using 100% recycled polyester to create their signature line of golf shirts, with some planning to reach 75% recycled polyester use by 2025. These materials offer several advantages:

Premium Golf Fabrics from Recycled Sources:

-

Recycled polyester maintains the moisture-wicking properties essential for golf performance

-

Reduced carbon footprint compared to virgin materials

-

Durability that matches or exceeds traditional fabrics

-

Cost-effectiveness for bulk golf shirts and custom orders

Innovative Material Technologies:

The integration of advanced materials like graphene-infused golf wear temperature control represents the cutting edge of sustainable innovation. These materials provide superior temperature regulation while being produced through more environmentally friendly processes.

4-Way Stretch Golf Pants: Performance Meets Sustainability

Modern golfers demand unrestricted movement, and 4-way stretch golf pants with ISO 13934 certified materials deliver this performance while meeting strict environmental standards. These fabrics combine recycled fibers with innovative weaving techniques to create garments that move naturally with the golfer's swing while maintaining their shape and durability over time.

Low MOQ Solutions: Supporting Golf Apparel Startups

One of the most significant barriers for golf apparel startups has traditionally been high minimum order quantities (MOQs). However, sustainable manufacturing has opened new possibilities for low MOQ golf apparel 50 pieces, making it easier for emerging brands to enter the market.

Custom Golf Wear Solutions for Every Brand

Personalized Golf Wear Options:

-

Custom logo sport golf shirts with embroidery or printing

-

Unique ladies' golf apparel designed for specific market segments

-

Custom embroidered golf polo shirts for corporate clients

-

Funny golf shirts that capture brand personality

Flexible Manufacturing Approach:

Leto Golf's approach to custom golf shirts emphasizes flexibility without compromising sustainability. Whether you need 50 pieces for a startup launch or bulk golf shirts for an established brand, sustainable manufacturing processes can accommodate various order sizes while maintaining consistent quality and environmental standards.

Advanced Manufacturing Technologies

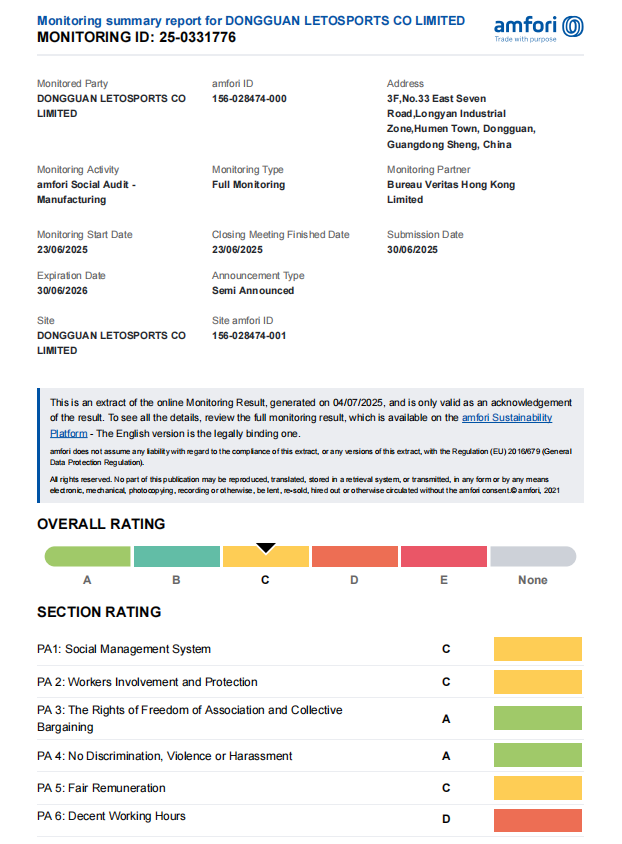

BSCI Audited Golf Wear Factory Standards

A BSCI audit is a thorough evaluation of a company's adherence to ethical standards, including labor rights and environmental practices. Working with a BSCI audited golf wear factory ensures that your golf clothing solutions meet international standards for:

-

Worker safety and fair labor practices

-

Environmental protection measures

-

Quality control systems

-

Sustainable production methods

Technical Testing and Certifications

AATCC 183 UV Test Methodology:

Sun protection is crucial for golf apparel, and AATCC 183 UV test methodology ensures that fabrics provide adequate protection while maintaining sustainability standards. This testing validates that eco-friendly materials don't compromise on the UV protection golfers need during long rounds.

ISO Standards Compliance:

Adherence to international standards ensures that sustainable golf apparel meets global quality and performance requirements, giving brands confidence in their product offerings.

Specialized Golf Apparel Solutions

Ladies' Golf Apparel: Style Meets Sustainability

The ladies' golf apparel market has seen tremendous growth, with brands seeking cute golf outfits for ladies that combine fashion-forward designs with sustainable materials. Luxury golf apparel brands ladies segment particularly values:

-

Sustainable fabrics that maintain a premium feel and appearance

-

Innovative designs that flatter while allowing a full range of motion

-

Color-fast dyeing processes that use less water and energy

-

Packaging solutions that minimize environmental impact

Performance-Driven Innovations

Climate-Specific Solutions:

-

Sweat-resistant golf wear for tropical climates using moisture-wicking recycled fibers

-

Windproof golf jacket for coastal tournaments, manufactured with sustainable materials

-

Lightweight golf vest tournament legal design that meets competition requirements

Mobility and Comfort:

Non-restrictive golf polo full swing mobility remains a priority, achieved through innovative pattern making and sustainable stretch fabrics that move naturally with the golfer's body.

Manufacturing Excellence: The Leto Golf Advantage

Comprehensive Production Capabilities

Leto Golf's commitment to sustainable manufacturing encompasses every aspect of production:

Advanced Equipment and Technology:

-

State-of-the-art printing and embroidery equipment for custom embroidered golf apparel

-

Water-efficient dyeing processes that reduce environmental impact

-

Energy-efficient manufacturing facilities

-

Waste reduction systems throughout the production line

Skilled Craftsmanship:

Our team combines traditional garment-making skills with modern sustainable practices, ensuring that every piece meets the highest standards of quality while minimizing environmental impact.

Quality Control and Testing

Rigorous Testing Protocols:

-

Fabric performance testing for durability and wash-fastness

-

Fit testing to ensure optimal comfort and mobility

-

Environmental impact assessment for all materials and processes

-

Color matching and consistency verification

Continuous Improvement:

Regular audits and assessments ensure that our sustainable practices evolve with industry best practices and technological advances.

Trendy Golf Apparel: Balancing Style and Sustainability

Innovative Golf Fashion Trends

Smart fabrics embedded with sensors could track performance data, such as swing speed, heart rate, and body posture, representing the future of innovative golf fashion. However, sustainability remains paramount in these developments, with manufacturers focusing on:

-

Biodegradable electronic components

-

Recyclable smart fabric constructions

-

Energy-efficient production methods for tech-enabled apparel

-

Minimal packaging for electronic components

Design Versatility

Modern golf apparel serves multiple purposes, transitioning seamlessly from course to clubhouse to casual wear. This versatility reduces the overall environmental impact by maximizing garment utility and extending product lifecycles.

Country Club Uniform Redesign: A Case Study in Sustainability

Challenges and Solutions

When approached by a prestigious country club for uniform redesign, Leto Golf faced the challenge of creating apparel that would:

-

Maintain the club's traditional aesthetic

-

Incorporate sustainable materials

-

Provide superior comfort for staff working long hours

-

Meet durability requirements for frequent washing

Implementation Strategy

Material Selection:

-

70% recycled polyester blend for durability and easy care

-

Natural fiber components for breathability and comfort

-

UV-resistant treatments using eco-friendly processes

-

Stain-resistant finishing without harmful chemicals

Design Innovation:

-

Classic styling with subtle modern updates

-

Hidden stretch panels for enhanced mobility

-

Moisture-wicking properties integrated into traditional fabrics

-

Logo placement optimized for both aesthetics and durability

Results:

The redesigned uniforms received overwhelmingly positive feedback from both staff and members, demonstrating that sustainable practices can enhance rather than compromise traditional golf apparel excellence.

Embroidery Golf Hat Minimum Quantity: Accessory Solutions

Golf accessories, including hats and caps, play a crucial role in complete apparel solutions. For embroidery golf hat minimum quantity orders, sustainable practices include:

-

Organic cotton and recycled fiber hat constructions

-

Water-based embroidery threads

-

Minimal packaging using recycled materials

-

Local sourcing to reduce transportation impacts

The Business Case for Sustainable Golf Apparel

Cost-Effectiveness

Contrary to common misconceptions, sustainable golf apparel manufacturing can be cost-effective, especially when considering:

Long-term Benefits:

-

Reduced material costs through recycling programs

-

Energy savings from efficient manufacturing processes

-

Enhanced brand reputation leading to premium pricing opportunities

-

Reduced regulatory compliance costs

Market Positioning:

Brands that embrace sustainability early position themselves advantageously as consumer preferences continue to shift toward environmentally conscious products.

Consumer Response

The most sustainable golf clothing brands use innovative materials that are low-impact and high-performing while reducing waste, and consumers are responding positively to these offerings. Market research indicates that golfers are willing to pay premium prices for apparel that aligns with their environmental values while delivering superior performance.

Future Trends in Sustainable Golf Apparel

Emerging Technologies

The intersection of sustainability and technology continues to evolve, with developments including:

-

Biodegradable performance fabrics

-

Closed-loop recycling systems

-

AI-optimized manufacturing for waste reduction

-

Blockchain supply chain transparency

Circular Economy Integration

The golf apparel industry is moving toward circular economy principles, where products are designed for reuse, recycling, and minimal waste generation throughout their lifecycle.

Choosing the Right Golf Clothing Manufacturer

Key Considerations for Buyers

When selecting golf clothing suppliers, consider these sustainable practice indicators:

Certifications and Audits:

-

BSCI compliance for ethical manufacturing

-

ISO certifications for quality and environmental management

-

Organic and recycled material certifications

-

Third-party sustainability audits

Transparency and Communication:

-

Clear documentation of sustainable practices

-

Regular reporting on environmental impact improvements

-

Open communication about challenges and solutions

-

Collaborative approach to sustainability goals

Partnership Benefits

Working with a committed, sustainable manufacturer like Leto Golf provides:

-

Access to the latest eco-friendly materials and technologies

-

Expert guidance on sustainable design choices

-

Flexibility in order quantities to support business growth

-

Continuous innovation in sustainable practices

Conclusion: The Future is Green and Efficient

The golf apparel industry's transformation toward sustainable practices represents more than an environmental imperative—it's a business opportunity that forward-thinking brands cannot afford to ignore. From recycled golf apparel supplier partnerships to innovative materials like graphene-infused fabrics, the possibilities for creating exceptional golf clothing while protecting our environment are virtually limitless.

For golf apparel startups, procurement managers, and fashion buyers, the choice is clear: partnering with manufacturers who prioritize sustainability while maintaining excellence in quality, customization, and service. Leto Golf stands ready to support this vision, combining decades of manufacturing expertise with cutting-edge sustainable practices to create golf apparel that performs beautifully on the course while treading lightly on the earth.

The future of golf apparel is lean, green, and exceptionally efficient. By embracing these sustainable practices today, brands position themselves for long-term success in an increasingly environmentally conscious market. Whether you need custom embroidered golf apparel, bulk orders for established brands, or innovative solutions for emerging market segments, sustainable manufacturing offers the perfect combination of performance, style, and environmental responsibility.

As we move forward, the golf apparel industry will continue to evolve, but one thing remains constant: the commitment to creating exceptional products that honor both the game of golf and the planet we call home. Choose sustainability. Choose efficiency. Choose excellence. Choose Leto Golf for your sustainable golf apparel manufacturing needs.

Post time: 25-08-01