Introduction

The golf apparel industry is experiencing unprecedented growth, with the global golf apparel market expected to reach $16.7 billion by 2034. For golf apparel startups, established brands, and procurement managers, selecting the right manufacturing partner has become more critical than ever. With nearly 37% of new launches now incorporating eco-friendly materials such as organic cotton or recycled polyester and golf brands offering more opportunities for consumers to personalize their apparel, the manufacturing landscape has evolved dramatically.

This comprehensive guide will walk you through everything you need to know about comparing golf wear manufacturing companies, with particular emphasis on how Leto Golf Manufacturing stands out as a premier choice for brands seeking high-quality, customized solutions that meet the diverse needs of both startups and established enterprises.

Understanding the Modern Golf Apparel Manufacturing Landscape

Current Industry Trends Shaping Manufacturing Decisions

The golf apparel industry in 2025 is defined by several key trends that directly impact manufacturing choices. Eco-friendly materials, modern silhouettes, and comfort-focused designs reflect the evolving preferences of today's golfers. This shift has created new demands for manufacturers who must adapt to sophisticated requirements while maintaining competitive pricing and quality standards.

Advancements in apparel technology have revolutionized the golf apparel industry, with innovative fabrics and manufacturing techniques introducing moisture-wicking materials, UV protection, stretchability, and breathability features. These technological improvements have raised the bar for what customers expect from their golf wear manufacturing partners.

The Rise of Sustainable and Personalized Golf Apparel

Today's discerning golf apparel brands are increasingly focused on sustainability and personalization. The near future will see a rise in sustainable and eco-friendly fabrics in golf clothing, with brands using materials like organic cotton, recycled polyester, and bamboo blends. This trend toward environmental consciousness has made recycled golf apparel suppliers increasingly valuable partners for forward-thinking brands.

Key Factors to Consider When Comparing Golf Wear Manufacturing Companies

Manufacturing Capabilities and Equipment

When evaluating golf clothing solutions providers, the first consideration should be their manufacturing capabilities. A top-tier manufacturer like Leto Golf Manufacturing distinguishes itself through comprehensive printing and embroidery equipment that enables professional OEM/ODM services. This includes specialized machinery for custom embroidered golf apparel and the ability to handle complex designs with precision.

The best golf shirt suppliers invest heavily in state-of-the-art equipment that can accommodate various customization requests, from simple logo placement to intricate designs requiring multiple production techniques. Look for manufacturers that offer both traditional embroidery services and modern printing technologies to ensure your brand can achieve the exact aesthetic you envision.

Minimum Order Quantities and Flexibility

For golf apparel startups and smaller brands, finding a manufacturer that offers low MOQ golf apparel options with quantities as low as 50 pieces can be game-changing. This flexibility allows emerging brands to test markets, launch limited collections, and manage cash flow more effectively without compromising on quality.

Established golf clothing suppliers understand that not every order needs to be massive to be profitable. The ability to accommodate smaller orders while maintaining quality standards demonstrates a manufacturer's commitment to building long-term partnerships rather than just processing large-volume transactions.

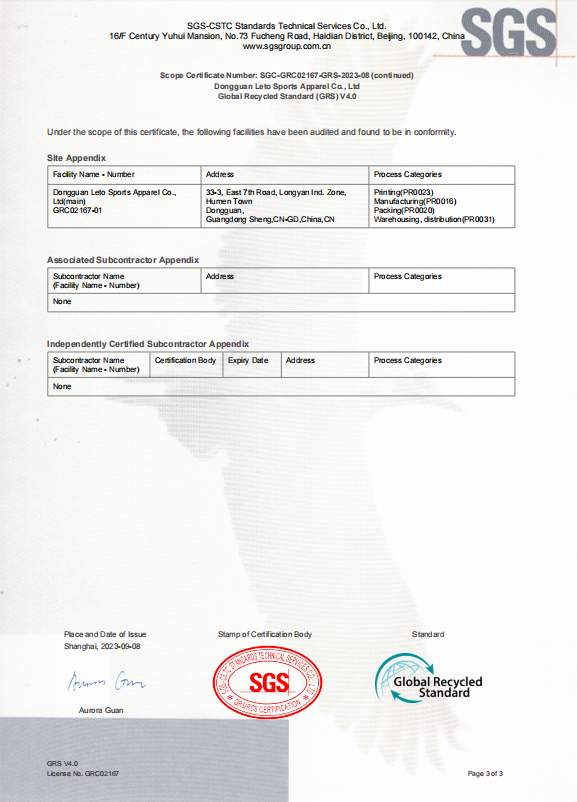

Quality Standards and Certifications

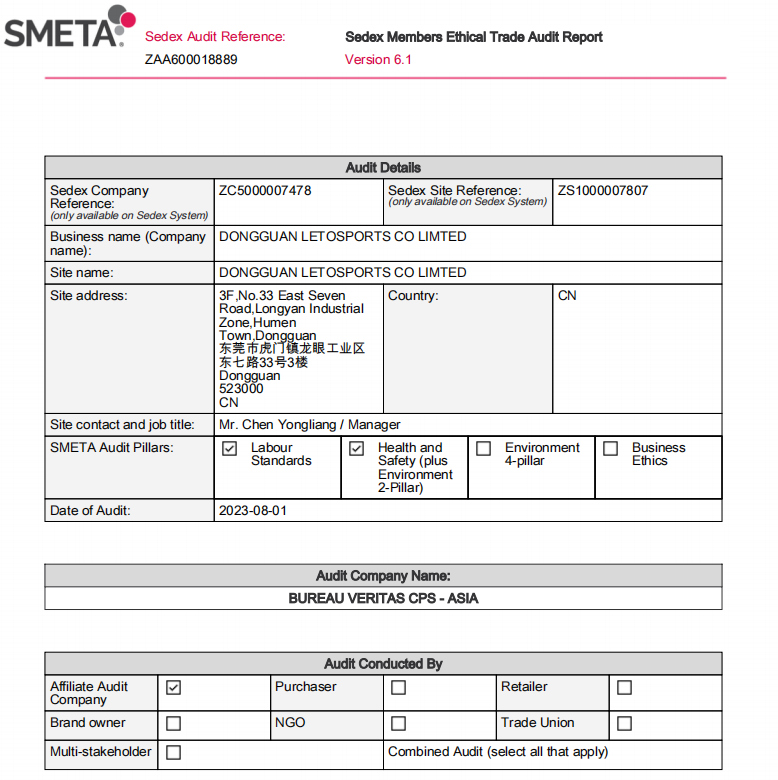

Professional golf wear manufacturing companies should maintain rigorous quality standards backed by internationally recognized certifications. The BSCI (Business Social Compliance Initiative) is a leading corporate social responsibility initiative that promotes ethical labor practices and work conditions. A BSCI audited golf wear factory provides assurance that your manufacturing partner adheres to ethical business practices.

Additionally, technical standards like AATCC 183 UV test methodology ensure that products meet specific performance criteria. For golf apparel, UV protection testing is particularly important given the outdoor nature of the sport and increasing consumer awareness of sun protection.

Material Innovation and Sourcing

The best golf clothing manufacturers stay ahead of material innovations. This includes sourcing premium golf fabrics that incorporate cutting-edge technologies like graphene infused golf wear temperature control systems and 4-way stretch golf pants that meet ISO 13934 standards for stretch and recovery.

Organic cotton golf wear suppliers are becoming increasingly important as brands respond to consumer demand for environmentally conscious products. There is an increasing consumer interest in sustainable and eco-friendly products, which is driving the demand for golf apparel crafted from recycled or organic materials.

Specialized Product Categories and Manufacturing Expertise

Performance-Driven Golf Apparel

Modern golfers demand more than just aesthetically pleasing clothing. They need functional garments that enhance their performance on the course. This includes non-restrictive golf polo designs that provide full swing mobility, lightweight golf vest tournament legal designs that comply with competition regulations, and sweat-resistant golf wear specifically engineered for tropical climates.

The best manufacturers understand these technical requirements and have the expertise to produce garments that meet specific performance criteria while maintaining comfort and style. This includes windproof golf jackets for coastal tournaments and other specialized items that address specific playing conditions.

Women's Golf Apparel Specialization

The ladies' golf apparel market presents unique opportunities and challenges. Manufacturers who specialize in unique ladies golf apparel understand the importance of combining functionality with fashion-forward design. This includes creating cute golf outfits for ladies that don't compromise on performance features.

Leading ladies golf apparel brands partner with manufacturers who understand the nuances of women's golf fashion, from fit considerations to style preferences. The ability to create trendy golf apparel that appeals to female golfers while maintaining technical performance standards requires specialized expertise.

Custom and Personalized Solutions

The demand for personalized golf wear has never been higher. This includes custom logo sport golf shirts, custom embroidered golf polo shirts, and comprehensive custom golf wear solutions that allow brands to differentiate themselves in a competitive market.

Manufacturers like Leto excel in providing customized design solutions that meet the diverse needs of both startups and established enterprises. This capability extends beyond simple logo application to include comprehensive design consultation and technical advice on achieving specific aesthetic and performance goals.

Evaluating Manufacturing Quality and Service Standards

Skilled Craftsmanship and Attention to Detail

The hallmark of exceptional golf wear manufacturing is skilled craftsmanship combined with meticulous attention to detail. This is evident in everything from embroidery golf hat minimum quantity requirements that don't compromise on quality to the precise execution of complex multi-color designs.

Quality manufacturing also means understanding the specific requirements of different product categories. For example, tournament-legal designs must meet specific regulations, while casual wear can focus more on comfort and style flexibility.

Efficient Manufacturing Processes

In today's fast-paced fashion environment, efficient manufacturing processes are crucial for success. The best golf clothing manufacturers have streamlined their operations to provide quick turnaround times without sacrificing quality. This includes efficient order processing, clear communication throughout the production cycle, and reliable delivery schedules.

Leto Golf Manufacturing exemplifies this approach through methodical and detailed service practices that prioritize customer value creation. This commitment to efficiency extends from initial design consultation through final delivery, ensuring that every aspect of the manufacturing process adds value for the client.

Technical Innovation and Development

Leading manufacturers invest in continuous innovation to stay ahead of industry trends. This includes developing new fabric technologies, improving production techniques, and staying current with emerging market demands. The ability to offer innovative golf fashion solutions while maintaining practical manufacturability is a key differentiator.

Sustainability and Ethical Manufacturing Practices

Environmental Responsibility

Sustainability is on the rise as companies create recycled and sustainable golfing apparel in an effort to tap into green consumers. Eco-friendly golf apparel manufacturers for environmentally conscious brands must demonstrate genuine commitment to sustainable practices throughout their operations.

This includes responsible sourcing of materials, energy-efficient production processes, and waste reduction initiatives. The best manufacturers view sustainability not as a marketing strategy but as a fundamental business responsibility that creates long-term value for all stakeholders.

Social Compliance and Worker Welfare

Social audits such as BSCI create transparency and compel suppliers to disclose critical information, building trust between business partners and enabling informed decision-making. Ethical manufacturing practices are no longer optional—they're essential for brands that want to build lasting relationships with conscious consumers.

Making the Right Choice for Your Brand

Assessing Your Specific Needs

Before selecting a manufacturing partner, clearly define your specific requirements. Consider factors such as your target market, volume requirements, quality expectations, and timeline constraints. Whether you're launching funny golf shirts for a niche market or developing luxury golf apparel brands for ladies, your manufacturing partner should have relevant experience and capabilities.

Building Long-Term Partnerships

The best manufacturing relationships are built on mutual respect, clear communication, and shared commitment to quality. Look for partners who view your success as their success and who are willing to invest in understanding your brand's unique requirements and goals.

Evaluating Total Value Proposition

While cost is always a consideration, the lowest price doesn't always represent the best value. Consider the total value proposition, including quality consistency, service reliability, technical expertise, and the manufacturer's ability to support your brand's growth over time.

Why Leto Golf Manufacturing Stands Out

Leto Golf Manufacturing has established itself as a premier choice for golf apparel brands seeking a manufacturing partner that combines technical expertise with personalized service. With comprehensive printing and embroidery equipment enabling professional OEM/ODM services, Leto offers the flexibility and capability that modern golf apparel brands require.

The company's methodical and detailed service approach reflects a deep commitment to customer value creation. This is evident in their ability to accommodate low MOQ requirements while maintaining the same quality standards applied to larger orders. Whether you're a startup looking to test new product concepts or an established brand launching a new collection, Leto's flexible approach ensures your specific needs are met.

Leto's technical capabilities extend across the full spectrum of golf apparel manufacturing, from basic custom logo applications to complex multi-component designs requiring specialized production techniques. Their expertise in sustainable materials and eco-friendly production processes positions them as an ideal partner for brands focusing on environmental responsibility.

Conclusion

Selecting the right golf wear manufacturing partner is a critical decision that will impact your brand's success for years to come. The modern golf apparel landscape demands manufacturers who can combine technical expertise, quality consistency, sustainable practices, and personalized service to meet the evolving needs of today's market.

By carefully evaluating potential partners based on their manufacturing capabilities, quality standards, service approach, and alignment with your brand values, you can identify the manufacturing relationship that will support your long-term success. Companies like Leto Golf Manufacturing demonstrate how the right partner can provide not just manufacturing services, but comprehensive support for your brand's growth and development in the competitive golf apparel market.

The golf apparel industry will continue to evolve, with new technologies, materials, and consumer preferences shaping future opportunities. By choosing a manufacturing partner committed to innovation, quality, and customer success, you position your brand to capitalize on these opportunities while building lasting relationships with your customers.

Post time: 25-07-26