The golf apparel industry is experiencing unprecedented growth, with the global market valued at USD 4.5 billion in 2024 and expected to grow at a CAGR of 6.2%. As golf clothing startups and established brands seek reliable manufacturing partners, understanding the intricate process behind creating high-quality golf wear becomes crucial for procurement managers, fashion buyers, and entrepreneurs entering this lucrative market.

The Evolution of Golf Apparel Manufacturing: Meeting Modern Demands

Today's golf clothing solutions extend far beyond traditional polos and khakis. Modern manufacturers like Leto Golf are revolutionizing the industry by offering comprehensive custom golf wear solutions that cater to diverse market segments, from golf apparel startups requiring low MOQ golf apparel 50 pieces to luxury golf apparel brands ladies seeking premium fabrications.

The manufacturing landscape has shifted dramatically to accommodate sustainability demands. Sustainability in golf apparel will become a dominant trend in 2025, with golf apparel brands adopting eco-friendly materials such as recycled polyester and biodegradable fabrics. This transformation has positioned recycled golf apparel suppliers at the forefront of industry innovation.

Premium Golf Fabrics: The Foundation of Excellence

Technical Performance Materials

The journey from fabric to final stitch begins with material selection. Premium golf fabrics form the backbone of exceptional golf clothing, with manufacturers investing in cutting-edge textiles that deliver performance and comfort. Key innovations include:

4-Way Stretch Technology: Modern golf shirt suppliers utilize fabrics meeting 4-way stretch golf pants ISO 13934 standards, ensuring unrestricted movement during the golf swing. This technology is particularly crucial for non-restrictive golf polo full swing mobility designs.

Moisture Management Systems: Sweat-resistant golf wear for tropical climates incorporates advanced wicking technologies that transport moisture away from the skin, maintaining comfort throughout extended play sessions.

Temperature Regulation: Innovative manufacturers are integrating graphene infused golf wear temperature control technology, providing intelligent thermal management that adapts to changing weather conditions.

UV Protection: Following AATCC 183 UV test methodology, premium fabrics offer superior sun protection, essential for outdoor sports apparel.

Sustainable Material Revolution

The shift toward eco-friendly golf apparel for environmentally conscious brands has driven significant innovation in sustainable materials. Organic cotton golf wear suppliers for eco-conscious retailers are developing fabrics that maintain performance standards while reducing environmental impact. Many brands are adopting recycled materials to create high-performance golf apparel, with garments made from recycled plastic bottles and other sustainable sources.

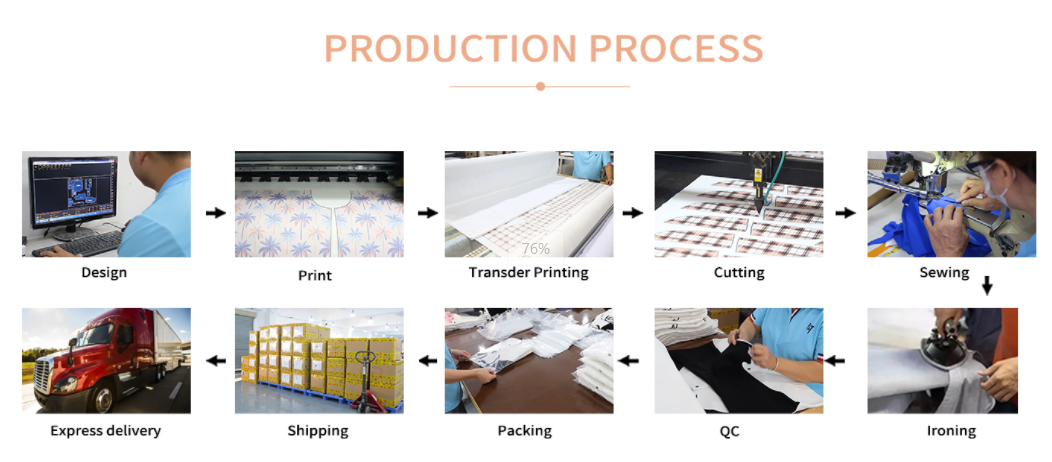

The Manufacturing Process: Skilled Craftsmanship Meets Technology

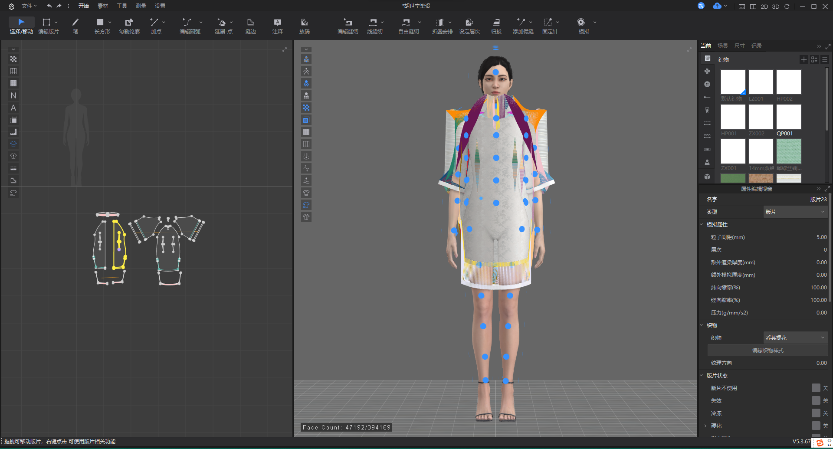

Design and Pattern Development

The manufacturing process begins with comprehensive design development, where experienced teams work closely with clients to create personalized golf wear that reflects brand identity. This stage involves:

-

Technical sketching and 3D modeling

-

Pattern grading for various sizes

-

Fit testing and adjustment protocols

-

Color matching and material sourcing

Quality Control at Every Stage

BSCI audited golf wear factories implement rigorous quality control measures throughout production. This systematic approach ensures consistent quality from initial cutting through final inspection, maintaining the high standards expected by golf clothing suppliers and their clients.

Specialized Equipment and Techniques

Modern golf apparel manufacturing facilities utilize state-of-the-art equipment for various applications:

Embroidery Capabilities: Advanced embroidery golf hat minimum quantity requirements can be accommodated through sophisticated multi-head machines capable of intricate designs and logos.

Digital Printing: Custom logo sport golf shirt production benefits from digital printing technologies that allow for complex graphics and unlimited color options.

Heat Transfer Applications: Lightweight golf vest tournament legal designs often incorporate heat-transferred elements that maintain the garment's performance characteristics.

Custom Solutions for Diverse Market Segments

Startup-Friendly Manufacturing

Golf apparel startups face unique challenges when entering the market. Leto Golf addresses these needs by offering:

-

Low minimum order quantities starting at 50 pieces

-

Flexible design consultation services

-

Rapid prototype development

-

Cost-effective production solutions

Ladies Golf Apparel Innovation

The women's golf market represents significant growth potential. Unique ladies golf apparel designs require specialized attention to fit, style, and performance. Ladies golf apparel brands benefit from manufacturers who understand the specific requirements for cute golf outfits for ladies that don't compromise on functionality.

Modern designs focus on:

-

Flattering silhouettes that enhance movement

-

Feminine color palettes and patterns

-

Performance features tailored to women's needs

-

Versatile pieces suitable for on and off-course wear

Professional and Tournament Requirements

Country club uniform redesign case studies demonstrate the importance of balancing tradition with modern performance needs. Professional applications require:

-

Consistent color matching across large orders

-

Durable construction for frequent washing

-

Professional appearance standards

-

Comfortable all-day wear characteristics

Innovative Golf Fashion: Technology Meets Style

Smart Textiles and Wearable Technology

Golf fashion apparel brands will be introducing wearable technology such as UV-sensing clothing and AI-based swing-enhancing clothing. This integration of technology represents the future of innovative golf fashion, where garments actively contribute to player performance.

Weather-Specific Solutions

Climate considerations drive specialized product development:

Windproof Protection: Windproof golf jackets for coastal tournaments utilize advanced membrane technologies that block wind while maintaining breathability.

Tropical Climate Adaptations: Specialized fabrics and construction techniques create sweat-resistant golf wear optimized for humid conditions.

Cold Weather Performance: Insulated layers and thermal regulation systems ensure comfort in challenging weather conditions.

The Art of Customization: From Concept to Creation

Custom Embroidered Golf Apparel

Custom embroidered golf polo shirts represent a significant portion of the golf apparel market. The embroidery process requires:

-

High-resolution digitization of logos and designs

-

Thread selection for durability and color fastness

-

Precise placement and sizing calculations

-

Quality control for stitch density and appearance

Personalization Technologies

Modern manufacturing capabilities enable extensive personalization options:

-

Individual name embroidery

-

Custom color combinations

-

Unique sizing accommodations

-

Special performance feature integration

Trendy Golf Apparel: Balancing Style and Performance

The evolution toward trendy golf apparel reflects changing consumer preferences. Gone are the days of dull and boring golf attire, with golfers embracing bold colors and eye-catching patterns. Funny golf shirts and expressive designs now coexist with traditional professional wear, requiring manufacturers to adapt to diverse style preferences.

Efficient Manufacturing: Streamlining Production Processes

Lean Manufacturing Principles

Efficient manufacturing processes are essential for competitive pricing and timely delivery. Key strategies include:

-

Waste reduction through precise cutting optimization

-

Streamlined workflow design

-

Automated quality control systems

-

Inventory management optimization

Supply Chain Integration

Successful golf clothing manufacturer operations depend on robust supply chain management:

-

Raw material sourcing relationships

-

Production scheduling coordination

-

Quality assurance protocols

-

Distribution logistics planning

Sustainable Manufacturing Practices

Environmental Responsibility

Brands are investing in responsibly sourced organic cotton and certified recycled polyester made from plastic bottles or recycled nylon from fishing nets. This commitment to sustainability extends throughout the manufacturing process:

-

Water conservation in dyeing processes

-

Energy-efficient production equipment

-

Waste reduction and recycling programs

-

Carbon footprint minimization

Ethical Manufacturing Standards

BSCI audited facilities ensure ethical labor practices and fair working conditions, addressing growing consumer awareness about supply chain responsibility.

Quality Assurance: Ensuring Excellence

Testing Protocols

Comprehensive testing ensures product reliability:

-

Fabric performance testing

-

Colorfastness evaluation

-

Durability assessments

-

Fit and comfort validation

Continuous Improvement

Regular process evaluation and improvement initiatives maintain competitive advantages and customer satisfaction.

Market Positioning and Brand Development

Understanding Target Markets

Successful golf apparel manufacturing requires deep understanding of diverse market segments:

-

Professional golfers requiring tournament-legal designs

-

Recreational players seeking comfortable, stylish options

-

Corporate clients needing branded uniforms

-

Fashion-conscious consumers wanting trendy designs

Competitive Advantages

Leto Golf's competitive positioning emphasizes:

-

Comprehensive customization capabilities

-

Sustainable manufacturing practices

-

Quality assurance protocols

-

Flexible order requirements

-

Expert design consultation

Future Trends and Innovation

The golf apparel industry continues evolving rapidly, driven by technological advancement and changing consumer preferences. Future developments will likely include:

-

Enhanced smart textile integration

-

Expanded sustainable material options

-

Improved performance characteristics

-

Greater customization capabilities

Conclusion: Partnership for Success

The golf outfit manufacturing process represents a complex interplay of technical expertise, creative design, and operational excellence. As the industry continues growing and evolving, partnerships between brands and experienced manufacturers like Leto Golf become increasingly valuable.

Whether you're a startup seeking low MOQ solutions, an established brand requiring premium customization, or a buyer looking for sustainable options, understanding the manufacturing process helps inform better decisions and achieve superior results. The future of golf apparel lies in the successful marriage of traditional craftsmanship with modern innovation, creating products that enhance both performance and style on the golf course.

Success in this dynamic market requires manufacturers who combine technical expertise with creative vision, offering comprehensive solutions that meet diverse client needs while maintaining the highest quality standards. Through careful attention to every aspect of the manufacturing process, from fabric selection to final stitch, exceptional golf apparel becomes reality.

Post time: 25-07-25