The golf apparel industry stands at a fascinating crossroads where tradition meets cutting-edge technology. While golfers have long prioritized style and comfort on the course, today's innovative fabrics are revolutionizing performance in ways that most players—and even industry insiders—don't fully understand. As a seasoned content marketing expert and golf apparel specialist, I've witnessed firsthand how fabric innovation is reshaping everything from startup brands to luxury golf apparel collections.

The Hidden Revolution in Golf Fabric Technology

When we talk about innovation in golf apparel fabrics, we're not just discussing minor improvements in comfort or durability. We're witnessing a fundamental transformation that's creating new opportunities for golf clothing suppliers, startups, and established brands alike. The most exciting developments are happening behind the scenes, where advanced materials science meets practical golf performance needs.

Graphene Infused Golf Wear Temperature Control: Perhaps the most groundbreaking advancement is the integration of graphene into golf fabrics. This revolutionary material, just one atom thick, provides unprecedented temperature regulation. Unlike traditional moisture-wicking fabrics that simply move sweat away from the body, graphene-infused materials actively regulate body temperature by conducting heat away from warm areas and insulating cooler zones. For golf apparel startups looking to differentiate themselves, this technology offers a compelling value proposition that goes far beyond conventional performance claims.

The implications for custom golf wear solutions are enormous. Imagine offering clients personalized golf wear that adapts to their specific body temperature patterns during a round. This isn't science fiction—it's available today through innovative manufacturing partnerships with facilities like Leto Golf Manufacturing, which has invested heavily in advanced fabric technologies.

Advanced Fabric Performance Standards That Matter

The golf apparel industry has established rigorous testing standards that separate premium products from mass-market alternatives. Understanding these standards is crucial for golf clothing manufacturers and buyers alike.

4-Way Stretch Golf Pants ISO 13934: This international standard measures fabric elasticity in all directions, ensuring that golf pants provide unrestricted movement during the swing. The ISO 13934 test evaluates tensile strength and elongation properties, guaranteeing that fabrics maintain their shape and performance after repeated stress. For golf apparel startups, specifying ISO 13934-compliant fabrics demonstrates commitment to quality and performance.

AATCC 183 UV Test Methodology: Sun protection has become a critical factor in golf apparel design, especially for tropical and coastal tournaments. The AATCC 183 standard measures ultraviolet protection factor (UPF) ratings, ensuring that fabrics provide adequate protection against harmful UV radiation. This is particularly important for ladies' golf apparel brands targeting health-conscious consumers who spend extended periods outdoors.

Sustainability: The New Competitive Advantage

Environmental consciousness is no longer a nice-to-have feature—it's becoming a market requirement. The most successful golf apparel brands are those that embrace sustainable practices without compromising performance.

Recycled Golf Apparel Supplier Networks: The emergence of suppliers specializing in recycled materials has created new opportunities for eco-friendly golf apparel. These suppliers work with post-consumer plastic bottles, recycled polyester, and other sustainable materials to create high-performance golf fabrics. For environmentally conscious brands, partnering with a recycled golf apparel supplier isn't just about marketing—it's about meeting genuine consumer demand for sustainable products.

Organic Cotton Golf Wear Supplier Solutions: While synthetic materials dominate performance golf wear, organic cotton remains popular for casual golf apparel and country club uniforms. The key is finding suppliers who can provide organic cotton fabrics that meet golf-specific performance requirements. This often involves blending organic cotton with performance synthetics to create fabrics that are both environmentally friendly and functionally superior.

Manufacturing Excellence: Where Innovation Meets Execution

The most innovative fabrics are worthless without skilled manufacturing partners who can translate cutting-edge materials into high-quality garments. This is where the expertise of established manufacturers becomes invaluable.

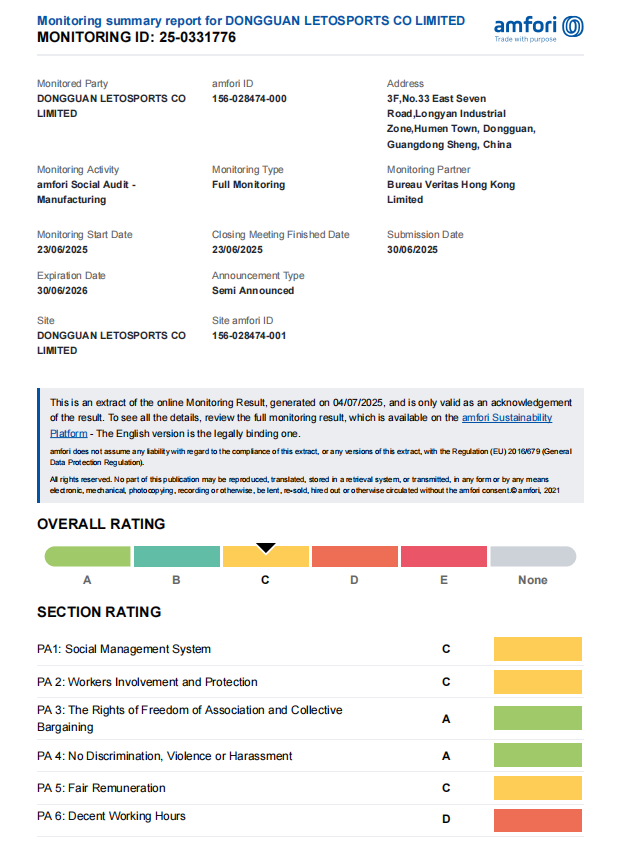

BSCI Audited Golf Wear Factory Standards: Social compliance has become increasingly important for golf apparel brands, particularly those targeting corporate and institutional markets. BSCI (Business Social Compliance Initiative) audited facilities ensure that manufacturing processes meet international labor and environmental standards. For golf apparel startups, partnering with BSCI-certified manufacturers provides credibility and peace of mind for socially conscious consumers.

Low MOQ Golf Apparel 50 Pieces: One of the biggest challenges facing golf apparel startups is the minimum order quantities. Traditional manufacturers often require orders of 1,000+ pieces per style, making it difficult for new brands to test markets or offer diverse product lines. Progressive manufacturers now offer low MOQ options, with some accepting orders as small as 50 pieces. This flexibility enables startups to experiment with innovative fabrics and designs without massive upfront investments.

Specialized Applications: Where Innovation Shines

The most exciting fabric innovations often emerge from addressing specific performance challenges that golfers face in different environments and situations.

Sweat-Resistant Golf Wear for Tropical Climates: Playing golf in hot, humid conditions requires fabrics that go beyond basic moisture-wicking. Advanced sweat-resistant technologies use micro-encapsulated cooling agents and phase-change materials to provide active cooling. These fabrics are particularly valuable for tournament play in tropical destinations where performance advantages can be significant.

Windproof Golf Jacket for Coastal Tournaments: Coastal golf courses present unique challenges, with sudden wind shifts and salt air affecting both comfort and performance. Windproof fabrics designed specifically for golf must balance protection with breathability and flexibility. The latest innovations use microporous membranes that block wind while allowing moisture vapor to escape, ensuring comfort during long rounds in challenging conditions.

Lightweight Golf Vest Tournament Legal Design: Tournament regulations often restrict certain types of apparel, making it crucial for manufacturers to understand and comply with various golf association rules. Lightweight golf vests designed for tournament play must meet specific thickness, design, and functionality requirements while providing meaningful performance benefits.

Customization and Personalization: The Future of Golf Apparel

The trend toward personalized golf wear is accelerating, driven by both consumer demand and technological capabilities. Modern manufacturing techniques make it possible to offer extensive customization options without prohibitive costs.

Custom Embroidered Golf Polo Shirts: Embroidery remains the gold standard for golf apparel customization, but modern techniques have evolved far beyond simple logo placement. Advanced embroidery systems can create complex designs, gradient effects, and even three-dimensional textures. For corporate golf programs and country club uniform redesign projects, custom embroidered polo shirts provide a professional appearance with personal touches.

Embroidery Golf Hat Minimum Quantity: Headwear presents unique customization challenges due to curved surfaces and varied materials. Many suppliers now offer embroidery golf hat services with minimum quantities as low as 12-24 pieces, making custom headwear accessible for small golf programs and promotional events.

Case Study: Country Club Uniform Redesign

A recent country club uniform redesign case study illustrates how innovative fabrics can transform traditional golf apparel. The project involved replacing outdated polyester uniforms with advanced performance fabrics that maintained the club's traditional aesthetic while dramatically improving comfort and functionality.

The key challenges included:

-

Maintaining the club's traditional color scheme and design elements

-

Improving moisture management for staff working long hours outdoors

-

Ensuring durability for frequent laundering and daily wear

-

Meeting budget constraints while upgrading quality

The solution involved custom golf wear solutions that incorporated:

-

Moisture-wicking fabrics with antimicrobial treatments

-

UV protection rated at UPF 50+ for outdoor staff

-

Stretch panels in high-movement areas

-

Stain-resistant treatments for food service staff

-

Custom embroidered logos with the club's heritage design

The results exceeded expectations, with staff reporting significantly improved comfort and the club receiving positive feedback from members on the professional appearance of the new uniforms.

The Ladies Golf Apparel Revolution

The ladies golf apparel market deserves special attention, as it's driving much of the innovation in golf fashion and performance wear. Unique ladies golf apparel brands are pushing boundaries in both style and technology.

Cute Golf Outfits for Ladies: The demand for fashionable golf wear that doesn't compromise performance has led to innovative fabric treatments and construction techniques. Modern ladies golf apparel successfully combines runway-inspired designs with technical fabrics that perform under pressure. This has created opportunities for brands to differentiate themselves through style while maintaining the performance standards that serious golfers demand.

Luxury Golf Apparel Brands Ladies: The premium segment of the ladies golf market is particularly receptive to fabric innovations. Luxury golf apparel brands are incorporating advanced materials like graphene-infused fabrics, phase-change materials, and sustainable luxury fibers to create products that justify premium pricing through superior performance and environmental responsibility.

Technical Innovations You Haven't Heard About

While much attention focuses on visible innovations like moisture-wicking and stretch fabrics, some of the most significant advances are happening at the microscopic level.

Non-Restrictive Golf Polo Full Swing Mobility: Modern golf polos use advanced knit structures that provide stretch without elastic fibers. These fabrics use mechanical stretch created through specialized knitting techniques, resulting in garments that move with the golfer's swing while maintaining their shape over time. This innovation is particularly valuable for golf apparel startups looking to differentiate their products in a crowded market.

Premium Golf Fabrics: The definition of "premium" in golf fabrics has evolved beyond thread count and brand names. Today's premium golf fabrics incorporate multiple performance features: temperature regulation, UV protection, moisture management, odor resistance, and durability. The challenge for manufacturers is integrating these features without creating stiff, uncomfortable garments.

Manufacturing Partnerships: The Key to Success

Success in the golf apparel industry increasingly depends on manufacturing partnerships that can deliver both innovation and reliability. This is where companies like Leto Golf Manufacturing demonstrate their value through comprehensive capabilities and attention to detail.

Skilled Craftsmanship: The most advanced fabrics require skilled manufacturing techniques to realize their full potential. Proper cutting, sewing, and finishing techniques are essential for garments that perform as designed. This is particularly important for custom logo sport golf shirts, where precision in logo placement and garment construction directly impacts brand perception.

Efficient Manufacturing: In today's fast-paced market, efficiency doesn't mean rushing production—it means optimizing every step of the manufacturing process to deliver consistent quality on schedule. This includes efficient material sourcing, streamlined production workflows, and rigorous quality control processes.

Future Trends and Opportunities

The golf apparel fabric innovation landscape continues to evolve rapidly, creating new opportunities for brands that can adapt quickly to changing consumer preferences and technological possibilities.

Trendy Golf Apparel: The intersection of fashion and function continues to drive innovation in golf apparel. Trendy golf apparel that incorporates the latest fabric technologies while maintaining style relevance requires close collaboration between designers, fabric technologists, and manufacturers.

Innovative Golf Fashion: The future of golf fashion lies in fabrics that can adapt to multiple conditions and preferences. Smart fabrics that change properties based on environmental conditions, body temperature, or even golfer preferences represent the next frontier in golf apparel innovation.

Conclusion: The Future is Here

The innovations in golf apparel fabrics we've explored aren't theoretical developments—they're available today through partnerships with forward-thinking manufacturers who understand both the technical requirements and market demands of modern golf apparel.

For golf apparel startups, the key to success lies in understanding these innovations and finding manufacturing partners who can help bring advanced concepts to market efficiently and cost-effectively. For established brands, staying competitive requires continuous evaluation of new fabric technologies and their potential applications.

The golf apparel industry is experiencing a renaissance of innovation, driven by advancing materials science, environmental consciousness, and changing consumer expectations. The brands that will succeed are those that embrace these innovations while maintaining the quality, performance, and style that golfers demand.

Whether you're launching a new golf apparel brand, redesigning existing products, or exploring opportunities in sustainable golf wear, the fabric innovations we've discussed represent genuine opportunities to create differentiated products that deliver real value to golfers.

Post time: 25-07-18