In today's fast-paced golf apparel market, supply chain efficiency isn't just a competitive advantage—it's a necessity for survival. Whether you're launching a Golf Apparel Startup or managing procurement for an established brand, understanding how to streamline your manufacturing process can make the difference between success and failure. As an experienced Golf Clothing Manufacturer, Leto has witnessed firsthand how efficient manufacturing processes transform businesses, reduce costs, and accelerate time-to-market for golf apparel brands of all sizes.

The Modern Golf Apparel Supply Chain: Challenges and Opportunities

The golf apparel industry faces unique supply chain challenges that require specialized solutions. Unlike fast fashion, golf clothing demands durability, performance, and adherence to strict quality standards. The traditional supply chain model, with its lengthy lead times and high minimum order quantities, no longer serves the dynamic needs of modern golf brands.

Market Dynamics: Today's golf apparel market is characterized by rapid trend cycles, seasonal fluctuations, and increasing demand for customization. Golf Apparel Startups particularly struggle with traditional manufacturing models that require large upfront investments and lengthy production cycles. The solution lies in partnering with manufacturers who understand these challenges and offer flexible, efficient alternatives.

Quality Standards: Golf apparel must meet stringent performance requirements, from 4-way stretch golf pants ISO 13934 compliance to AATCC 183 UV test methodology standards for sun protection. These requirements necessitate specialized manufacturing capabilities and quality control processes that not all suppliers can provide.

Sustainability Imperatives: Modern consumers increasingly demand Eco-friendly golf apparel for environmentally conscious brands. This shift requires manufacturers to offer recycled golf apparel supplier services and organic cotton golf wear supplier for eco-conscious retailers, adding complexity to the supply chain.

Efficient Manufacturing: The Foundation of Supply Chain Success

Efficient Manufacturing begins with understanding that one size doesn't fit all in the golf apparel industry. Different brands have varying needs, from luxury golf apparel brands' ladies segments requiring premium materials and finishing, to budget-conscious startups seeking cost-effective solutions without compromising quality.

Flexible Production Capabilities: Modern manufacturing efficiency stems from flexibility. Our low MOQ golf apparel 50 pieces service exemplifies this approach, allowing small brands to access professional manufacturing without prohibitive minimum orders. This flexibility extends to our embroidery golf hat minimum quantity requirements, designed to accommodate businesses at every stage of growth.

Technology Integration: Efficient manufacturing leverages cutting-edge technology to enhance productivity and quality. Our facilities incorporate advanced equipment for Custom Embroidered Golf Polo Shirts production, ensuring consistent quality while maintaining rapid turnaround times. The integration of graphene-infused golf wear temperature control technology represents our commitment to innovation in performance apparel.

Quality Systems: Operating as a BSCI audited golf wear factory, we maintain rigorous quality standards throughout the production process. This systematic approach ensures that efficiency never comes at the expense of quality, a crucial balance in golf apparel manufacturing.

Customization Without Compromise: Meeting Diverse Market Needs

The modern golf apparel market demands customization across multiple dimensions—from Personalized Golf Wear for individual customers to Custom Golf Wear Solutions for corporate clients. Efficient manufacturing systems must accommodate this diversity while maintaining cost-effectiveness and quality standards.

Design Flexibility: Our comprehensive design capabilities support everything from Custom Logo Sport Golf Shirt production to complex Custom Embroidered Golf Apparel projects. The key to efficiency lies in modular design systems that allow for customization without requiring complete production line reconfiguration.

Material Innovation: Premium Golf Fabrics form the foundation of superior golf apparel. Our material selection includes non-restrictive golf polo full swing mobility fabrics that enhance performance while maintaining a professional appearance. For specialized applications, we offer windproof golf jackets for coastal tournaments, materials, and sweat-resistant golf wear for tropical climates.

Women's Apparel Specialization: The women's golf apparel market presents unique opportunities and challenges. Ladies' golf apparel brands require specialized design considerations that balance performance with style. Our expertise in creating Unique ladies' golf apparel and Cute golf outfits for ladies demonstrates our understanding of this specialized market segment.

Case Study: Country Club Uniform Redesign Success Story

A recent country club uniform redesign case study illustrates how efficient manufacturing can transform traditional apparel programs. The project involved modernizing staff uniforms for a prestigious golf club while maintaining professional standards and controlling costs.

Challenge Assessment: The client faced several challenges: outdated uniform designs that lacked modern performance features, high replacement costs due to poor durability, and staff complaints about comfort during long shifts. The existing supplier couldn't accommodate the club's desire for customization without significant cost increases.

Solution Development: Our team developed a comprehensive solution that addressed each challenge systematically. We created Custom Golf Wear Solutions that incorporated modern performance fabrics while maintaining the club's traditional aesthetic. The new designs featured 4-way stretch golf pants with ISO 13934-compliant materials for improved comfort and mobility.

Implementation Strategy: The project utilized our low MOQ golf apparel 50-piece capability for initial sampling and testing. This approach allowed the client to evaluate multiple design options without a significant financial commitment. Once approved, full production commenced with Custom Embroidered Golf Apparel featuring the club's logo and branding elements.

Results and Impact: The redesigned uniforms improved staff satisfaction while reducing replacement costs by 30%. The enhanced professional appearance contributed to improved guest perception and employee pride. Most importantly, the project demonstrated how efficient manufacturing could deliver superior results at competitive costs.

Sustainable Manufacturing: Environmental Responsibility Meets Efficiency

Sustainable Golf Apparel production represents a growing market segment that requires specialized manufacturing capabilities. Environmental consciousness doesn't have to compromise efficiency—in fact, sustainable practices often enhance operational efficiency through waste reduction and resource optimization.

Material Sourcing: Our recycled golf apparel supplier program utilizes post-consumer recycled materials without compromising quality or performance. This approach reduces environmental impact while meeting growing consumer demand for sustainable products. The organic cotton golf wear supplier for eco-conscious retailers program offers natural fiber options for brands targeting environmentally conscious consumers.

Production Processes: Eco-friendly golf apparel for environmentally conscious brands requires careful consideration of manufacturing processes, energy consumption, and waste management. Our facilities implement best practices to minimize environmental impact throughout production, from water usage in dyeing processes to energy-efficient equipment operation.

Certification Standards: Maintaining a BSCI audited golf wear factory status ensures compliance with international environmental and social responsibility standards. This certification provides brands with confidence in their supply chain sustainability while supporting efficient operations through systematic process improvements.

Innovation in Golf Fashion: Balancing Tradition and Technology

The golf industry's conservative traditions often clash with rapidly evolving fashion trends and technological innovations. Successful manufacturers must navigate this balance carefully, creating Innovative Golf Fashion that respects the sport's heritage while embracing modern performance requirements.

Technical Innovation: Features like lightweight golf vest tournament legal design demonstrate our ability to incorporate advanced materials and construction techniques while maintaining compliance with tournament regulations. This capability is crucial for brands serving competitive golfers who demand both performance and regulatory compliance.

Performance Integration: Non-restrictive golf polo full swing mobility technology exemplifies our commitment to performance-oriented design. These innovations enhance player experience without compromising traditional golf apparel aesthetics, a balance that requires a deep understanding of both technical requirements and market preferences.

Trend Responsiveness: Trendy Golf Apparel requires rapid response to changing fashion trends while maintaining golf-specific performance features. Our design team excels at creating contemporary styles that incorporate traditional golf elements, ensuring broad market appeal.

Specialized Solutions for Diverse Playing Conditions

Golf is played in diverse environments worldwide, from tropical resorts to coastal links courses. Efficient manufacturing must accommodate these varying requirements while maintaining cost-effectiveness and quality standards.

Climate-Specific Designs: Sweat-resistant golf wear for tropical climates requires enhanced moisture management and UV protection. Our AATCC 183 UV test methodology compliance ensures garments meet strict sun protection standards, crucial for players in high-UV environments.

Environmental Adaptations: Windproof golf jackets for coastal tournaments are designed to address the unique challenges of seaside golf courses, where wind and salt air can significantly impact comfort and performance. These specialized products require advanced material knowledge and construction techniques.

Temperature Control: Graphene-infused golf wear temperature control represents the cutting edge of thermal management technology. This innovation provides consistent comfort across varying temperature conditions, demonstrating our commitment to performance enhancement through material science.

Manufacturing Excellence: Quality Systems and Skilled Craftsmanship

Skilled Craftsmanship remains fundamental to golf apparel manufacturing excellence, even as technology advances. The combination of traditional techniques and modern efficiency creates products that meet the demanding standards of golf apparel consumers.

Quality Control: Comprehensive quality systems ensure consistent results across all production runs. From initial material inspection to final garment testing, every step incorporates quality checkpoints that maintain standards while supporting efficient production flow.

Workforce Development: Our skilled workforce represents a crucial competitive advantage. Continuous training programs ensure our team stays current with evolving techniques and technologies, supporting both quality improvement and efficiency enhancement.

Equipment Investment: State-of-the-art manufacturing equipment supports both efficiency and quality objectives. Our comprehensive printing and embroidery capabilities enable complex customization while maintaining rapid turnaround times.

Supply Chain Optimization: Beyond Manufacturing

True supply chain efficiency extends beyond manufacturing to encompass procurement, logistics, and customer service. Leto's comprehensive approach addresses every aspect of the supply chain to deliver superior value to our partners.

Procurement Strategy: Strategic sourcing relationships ensure reliable material availability while maintaining cost competitiveness. Our global supplier network provides access to Premium Golf Fabrics and specialty materials required for high-performance golf apparel.

Logistics Coordination: Efficient logistics systems ensure timely delivery while minimizing costs. Our experience with international shipping and customs procedures supports smooth operations for global brands.

Customer Service Excellence: Responsive customer service supports efficient operations by addressing issues quickly and preventing disruptions. Our dedicated account management approach ensures consistent communication and proactive problem-solving.

Technology Integration: Digital Solutions for Modern Manufacturing

Modern manufacturing efficiency relies heavily on technology integration. Digital solutions enhance every aspect of the production process, from design development to final delivery.

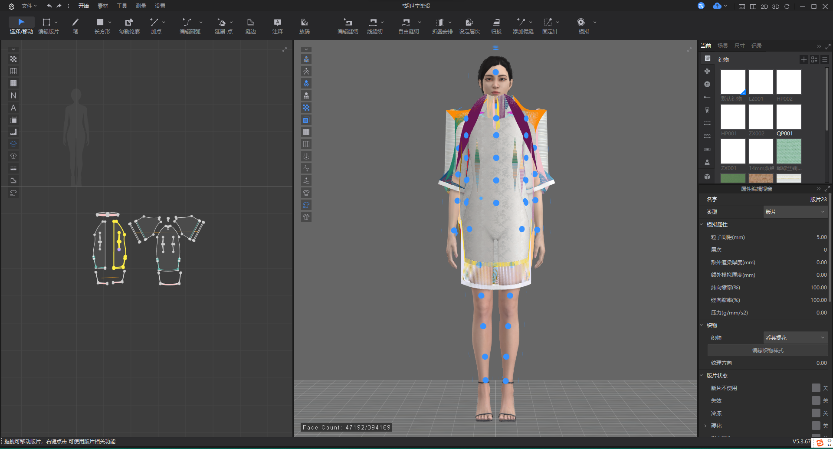

Design Technology: Advanced design software enables rapid prototype development and virtual sampling, reducing time-to-market while maintaining design quality. This capability is particularly valuable for Custom Golf Wear Solutions that require extensive client collaboration.

Production Management: Integrated production management systems provide real-time visibility into manufacturing progress, enabling proactive issue resolution and accurate delivery scheduling. This transparency supports efficient operations while building client confidence.

Quality Monitoring: Digital quality monitoring systems track product specifications throughout production, ensuring consistent results while supporting continuous improvement initiatives.

Future Trends: Anticipating Market Evolution

The golf apparel industry continues evolving, driven by technological advancement, changing consumer preferences, and environmental consciousness. Successful manufacturers must anticipate these trends while maintaining operational efficiency.

Sustainability Focus: Environmental consciousness will continue driving demand for Sustainable Golf Apparel solutions. Manufacturers must invest in sustainable processes and materials while maintaining cost competitiveness.

Customization Expansion: The Growing demand for Personalized Golf Wear will require enhanced customization capabilities. Efficient manufacturers must develop systems that support mass customization without compromising efficiency.

Performance Enhancement: Continued innovation in performance features will drive demand for advanced materials and construction techniques. Manufacturers must stay current with technological developments while maintaining practical production capabilities.

Conclusion: Partnership for Success

Streamlining your golf apparel supply chain requires more than just efficient manufacturing—it demands a partner who understands your unique challenges and opportunities. Leto's comprehensive approach combines Skilled Craftsmanship with modern efficiency, creating solutions that support your success in the competitive golf apparel market.

Whether you're launching a Golf Apparel Startup with low MOQ golf apparel 50 pieces requirements or managing procurement for established luxury golf apparel brands' ladies segments, our flexible manufacturing capabilities and commitment to quality ensure your success. Our BSCI audited golf wear factory status provides confidence in our processes, while our innovative approach to Custom Golf Wear Solutions supports your unique market positioning.

The future of golf apparel manufacturing lies in partnerships that combine efficiency with quality, innovation with tradition, and sustainability with performance. Through continued investment in people, processes, and technology, we help brands create products that enhance every golfer's experience while building sustainable business success.

Post time: 25-07-16